Low Pressure, Low Volume Tank Gas (LV/LP)

We believe capturing low volume, low pressure tank gas plays a crucial role in achieving zero emissions and meeting Environmental, Social, and Governance (ESG) goals in the oil and gas industry. Although these gas volumes may seem insignificant compared to larger gas streams, their cumulative impact on the environment, resource efficiency, and overall sustainability cannot be overlooked. Addressing this issue is essential for reducing greenhouse gas emissions, improving air quality, and fostering more sustainable and responsible energy production.

The importance of capturing low volume, low pressure tank gas for zero emissions and ESG goals includes:

Environmental benefits: Capturing and utilizing low volume, low pressure tank gas helps reduce the release of methane and other greenhouse gases into the atmosphere. Methane is a potent greenhouse gas, with a global warming potential significantly higher than that of carbon dioxide. By capturing and utilizing this gas, we can substantially reduce the overall environmental impact of oil and gas operations, contributing to ESG goals.

Resource efficiency: Capturing low volume, low pressure tank gas contributes to overall resource efficiency by ensuring that no valuable natural gas resources are wasted. This aligns with ESG goals by promoting responsible resource management and reducing waste.

Compliance and reputation: Oil and gas operators are increasingly facing regulatory and public scrutiny regarding their ESG performance. By capturing low volume, low pressure tank gas, operators can demonstrate their commitment to responsible and sustainable operations, meeting regulatory requirements, and improving their reputation within the industry and among the public.

There are several ways we capture and utilize low volume, low pressure tank gas, including:

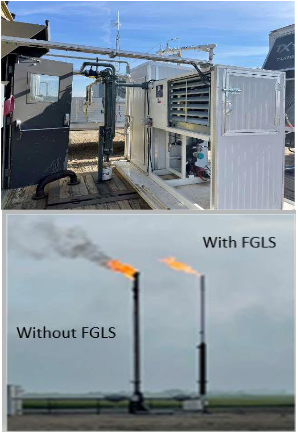

Vapor Recovery Units (VRUs): VRUs are mechanical systems designed to capture and compress low volume, low pressure tank gas, enabling its transportation and utilization. These systems can be installed at storage tank sites, ensuring that no gas is vented to the atmosphere and contributing to zero emissions goals.

On-site Liquefaction: LV/LP gas is “wet and rich” by nature. Meaning it has a higher % of C3+ Hydrocarbon than typical well gas. This leads to better than normal NGL Recovery and can be a lucrative stream of revenue that can offset operational costs. Beyond that, on newer sites and when volumes are higher, LNG equipment can be brought in to liquefy the remaining stream of Methane.

On-site Power Generation: By using LV/LP gas as fuel for on-site power generation, operators can generate electricity for their operations or integrate it into the local grid, creating additional revenue streams, and reducing the environmental impact of their activities.

We have multiple solutions for every size and scenario including sour gas situations. Please reach out with any questions or to inquire about our LV/LP Capture Brochure for more information.